Swing gate openers are widely used for residential, commercial, and industrial entrances due to their reliability and convenience. However, as outdoor equipment, they are constantly exposed to environmental factors — especially wind.

Strong winds can significantly affect the performance, stability, and service life of swing gate systems. Understanding these effects and applying proper installation and maintenance practices is essential to ensuring safe and reliable operation.

How Wind Affects Swing Gate Openers

1. Increased Motor Strain

Wind pressure can act on the gate leaf from either the front or the back as it opens or closes. Depending on the gate’s size and design, it may behave like a sail, catching wind and creating additional resistance.

When the gate moves against the wind, this resistance increases the mechanical load on the opener, forcing the motor to work harder. As a result, current draw rises, increasing the risk of motor overload or overheating.

2. Reduced Safety and Position Accuracy

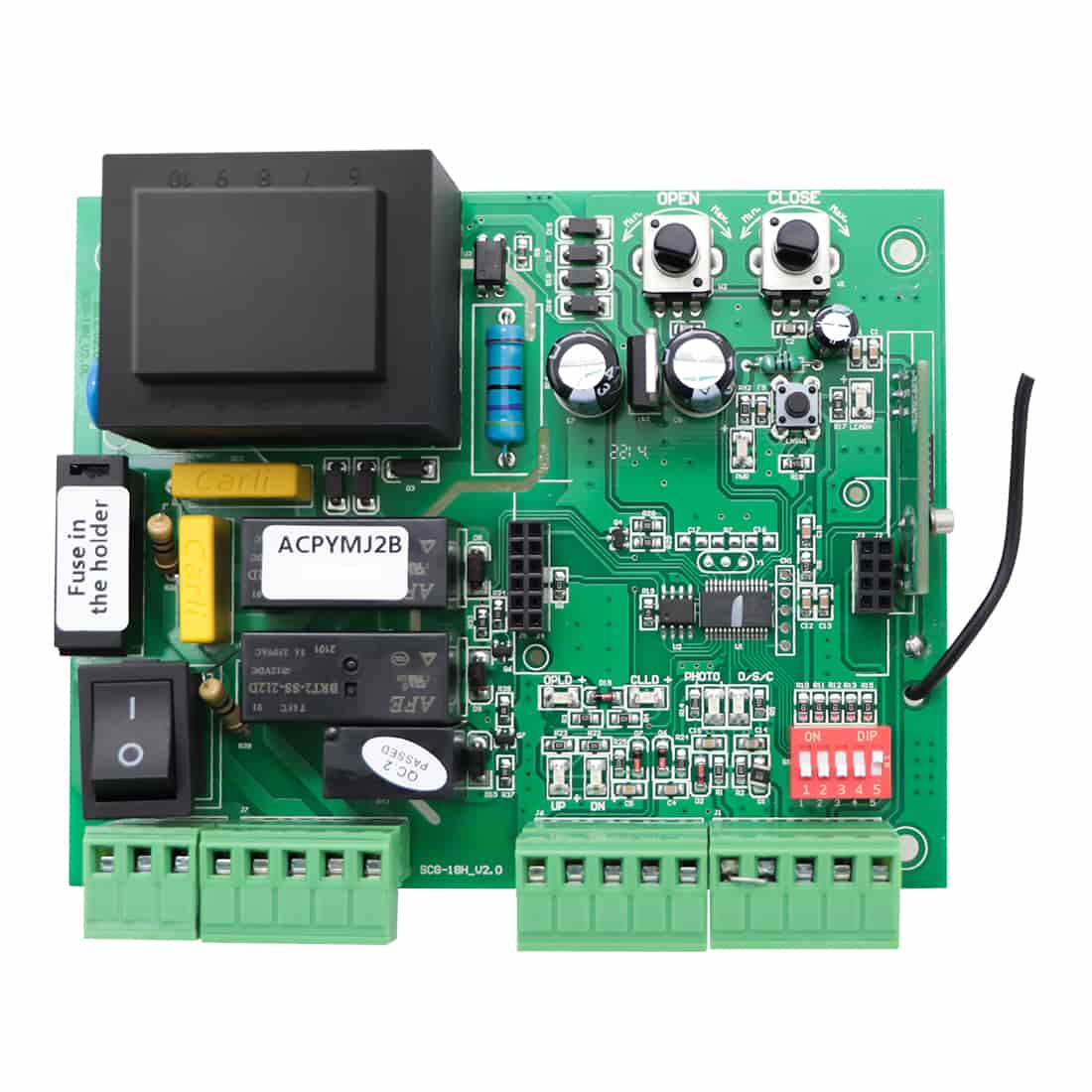

When the gate moves with the wind, the wind may push it faster than normal. This increases speed and inertia, which can cause the gate to overrun its fully open or closed position, reducing control and potentially compromising safety. In addition, the reduced resistance may lower the current draw below the opener’s detection threshold, triggering the safety protection system and causing the gate to stop unexpectedly. Strong gusts can also cause the gate to sway or rebound near its stop point, which may leave a gap between the gate leaves when closed.

Wind can also affect safety devices such as photocell sensors. Strong airflow may trigger false detections or delay sensor responses, leading to unintended stops, reopening, or irregular gate movement.

3. Accelerated Wear and Structural Stress

Continuous exposure to strong winds places additional stress on hinges, brackets, and mounting points, potentially loosening them over time.

The opener arm and connecting parts may also experience accelerated wear.

Large, solid gate panels — especially those made of iron or aluminum alloy — are more prone to deformation under prolonged wind pressure, reducing operational smoothness and shortening the gate system’s service life.

Recommended Installation Practices

- Install the system in areas with natural wind protection whenever possible.

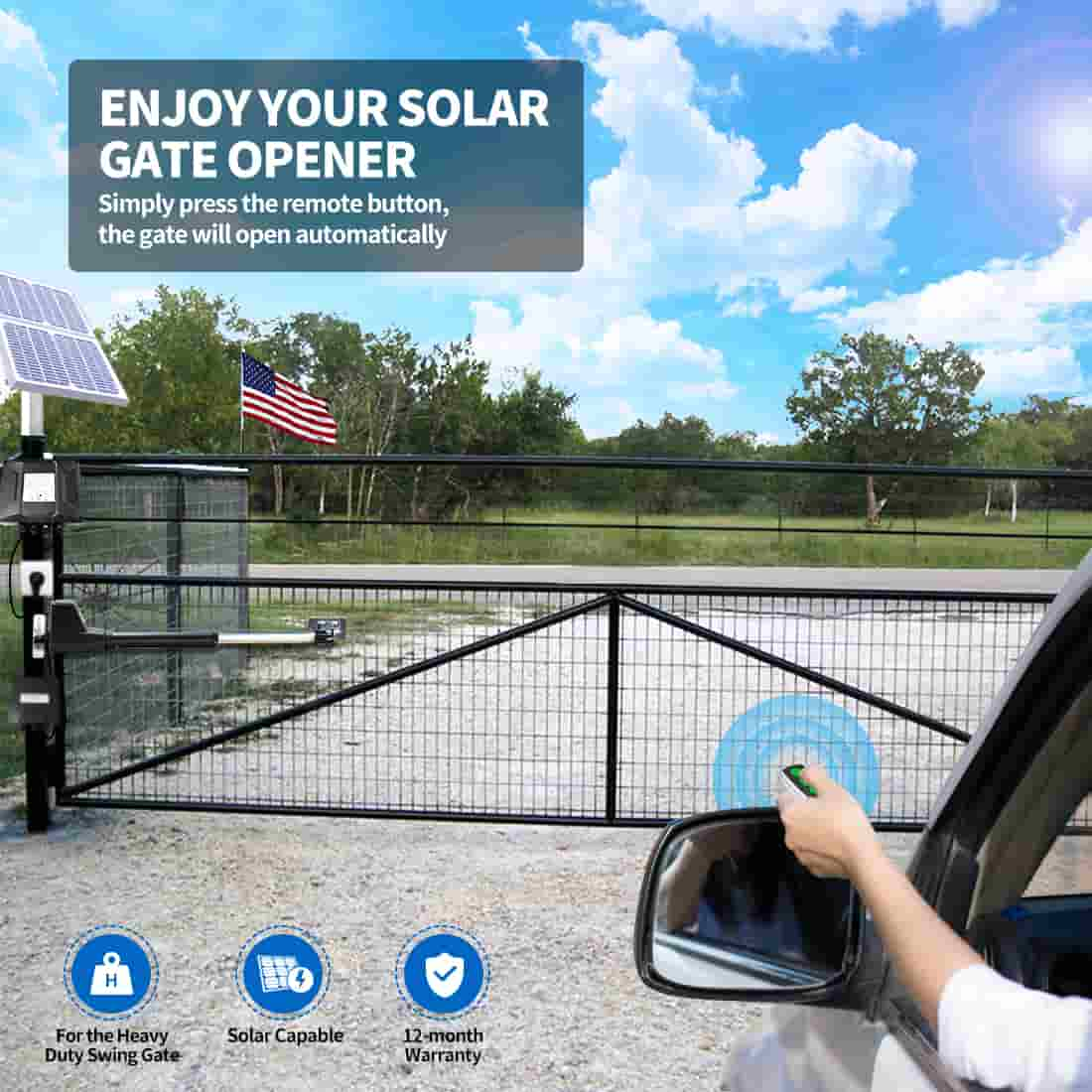

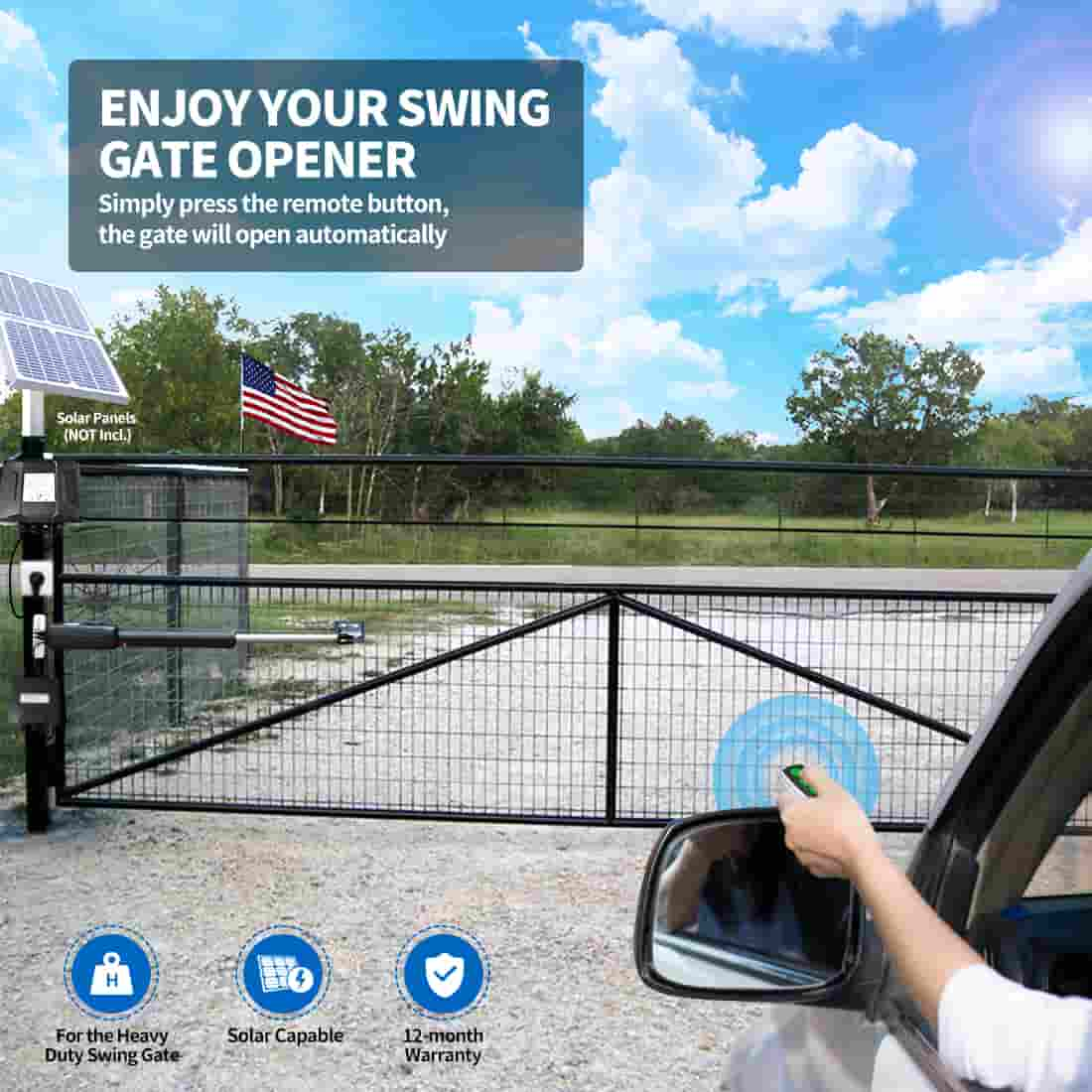

- In open or windy locations, use perforated or slatted gate panels to reduce wind resistance.

- Avoid large, solid gate panels that act like sails in high winds.

- Reinforce gate posts, hinges, and mounting brackets with heavy-duty bolts and steel supports.

- Add mechanical stops or wind braces to stabilize the gate in the fully open or closed position.

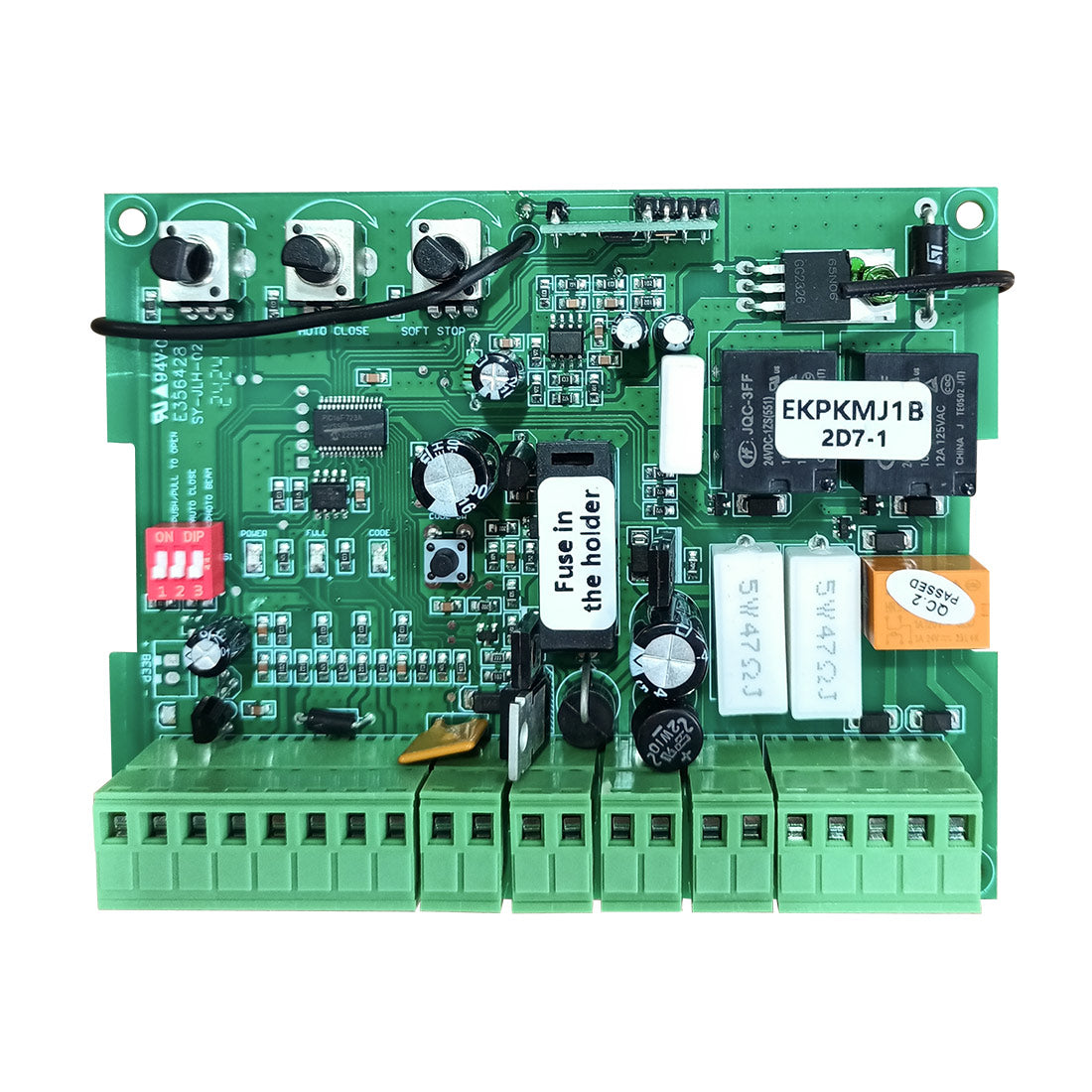

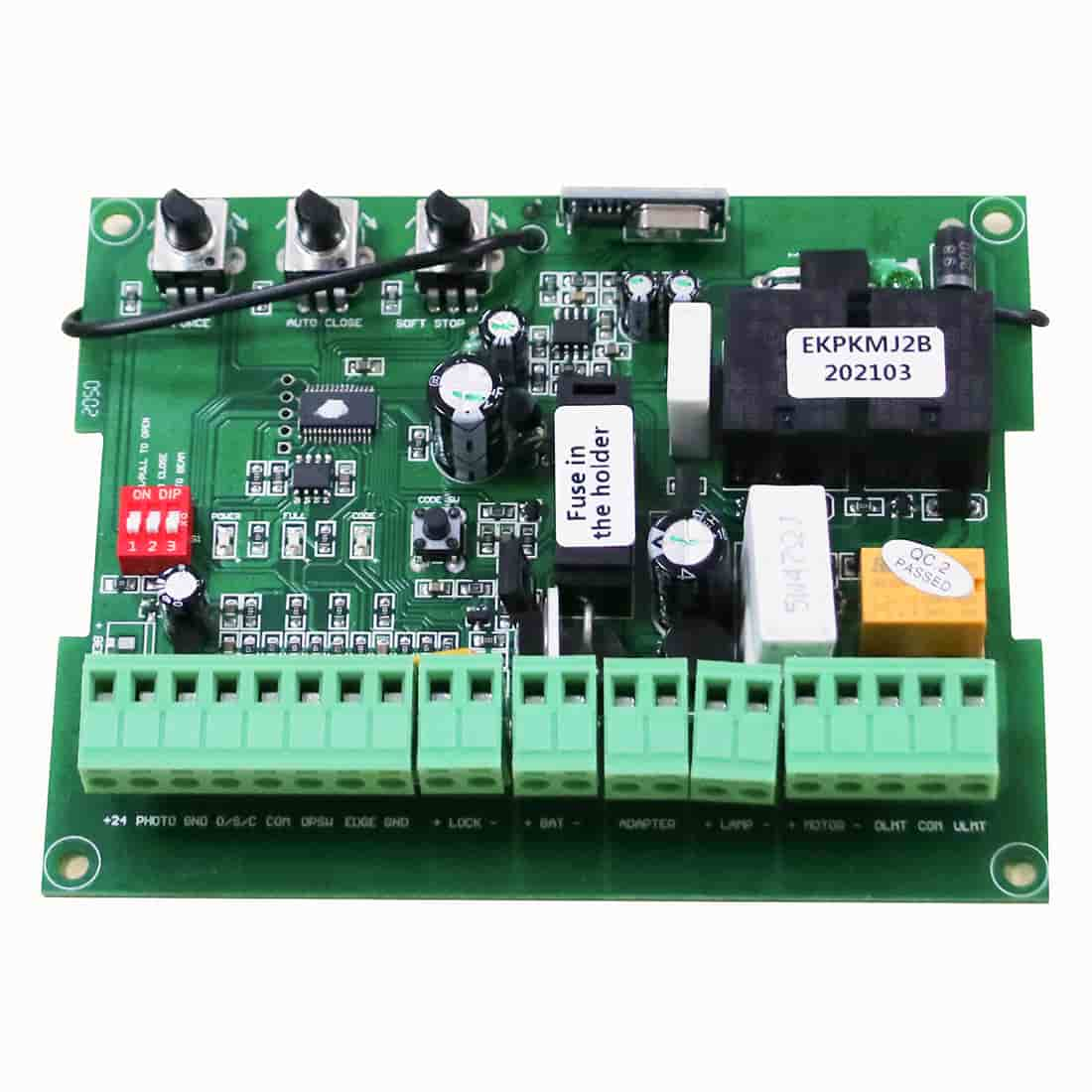

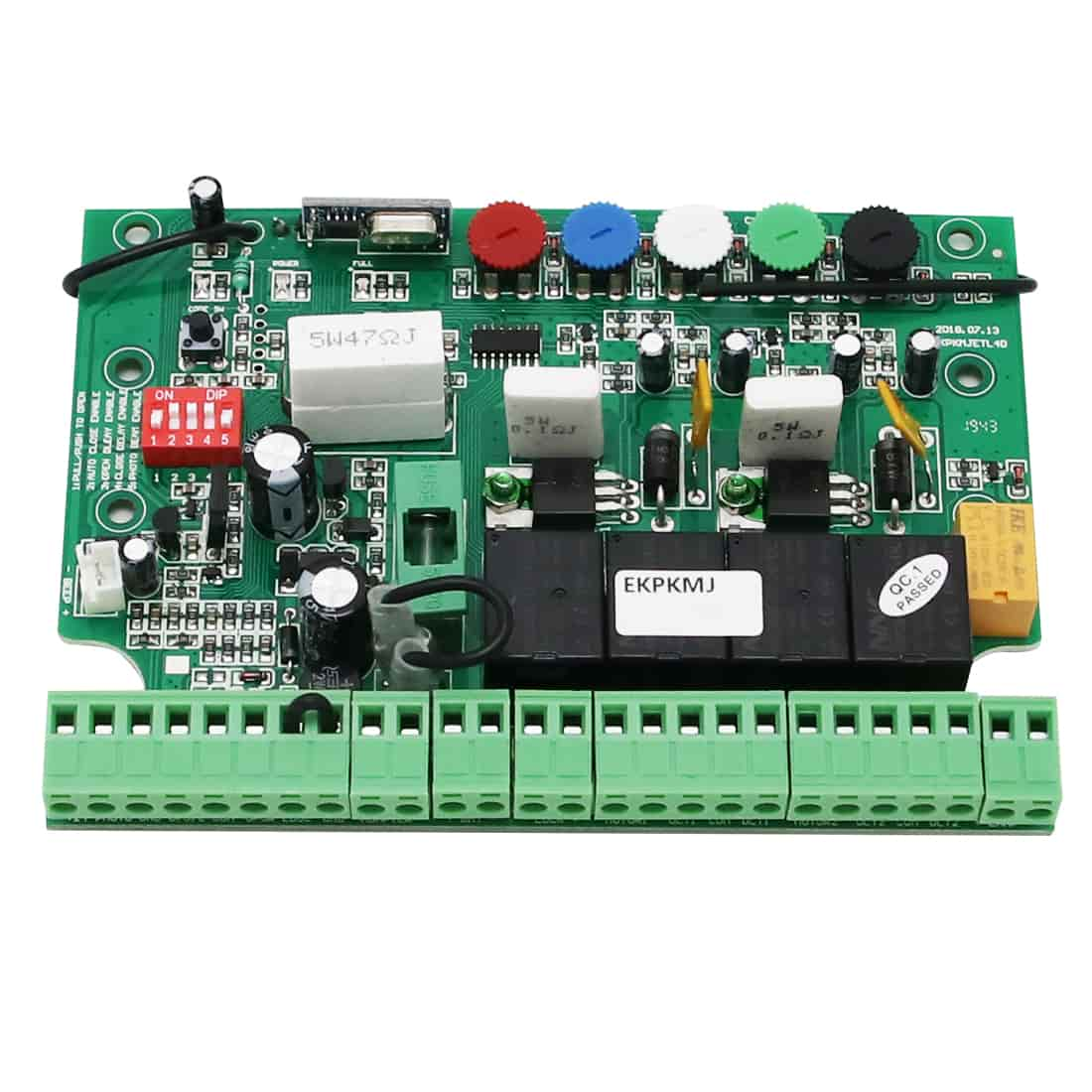

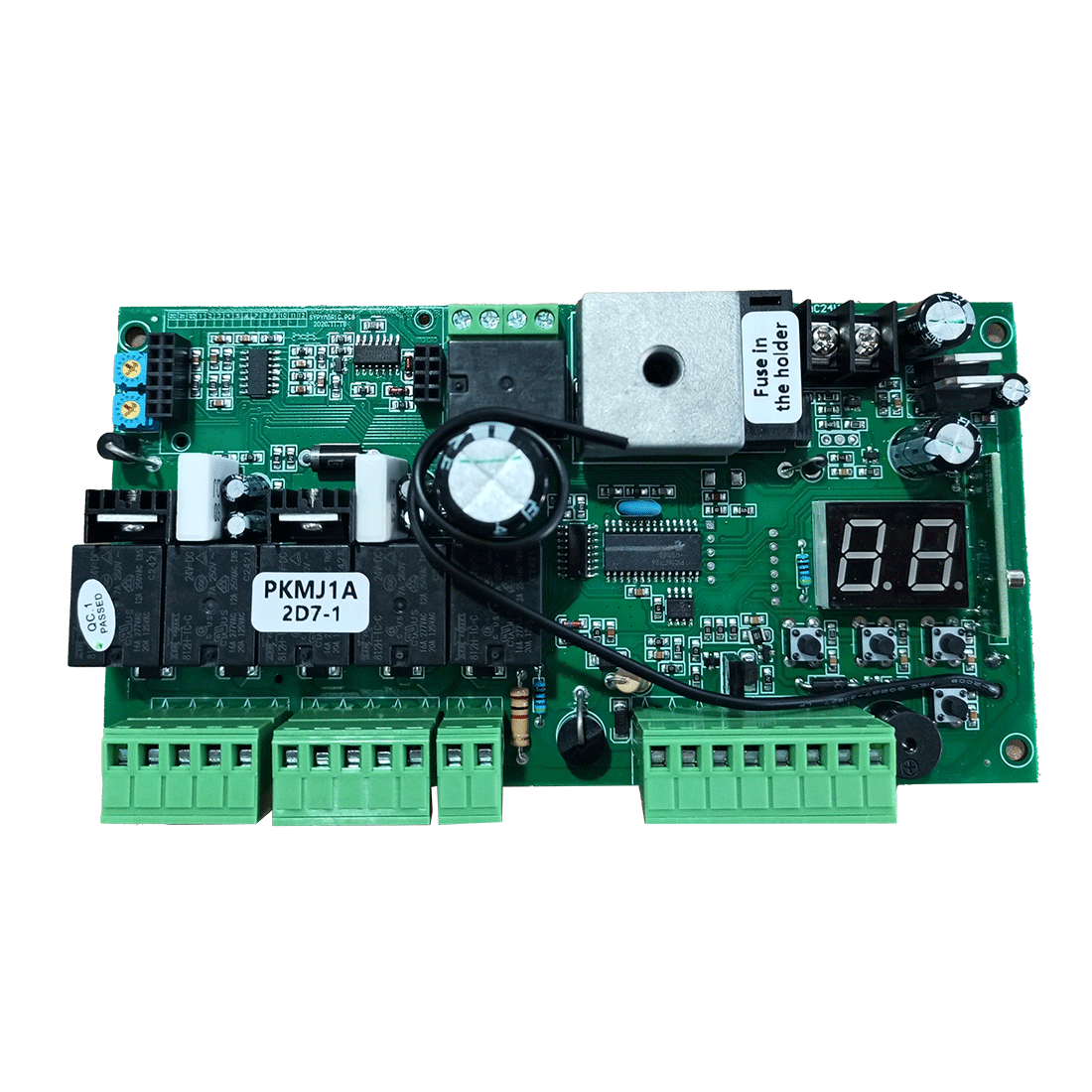

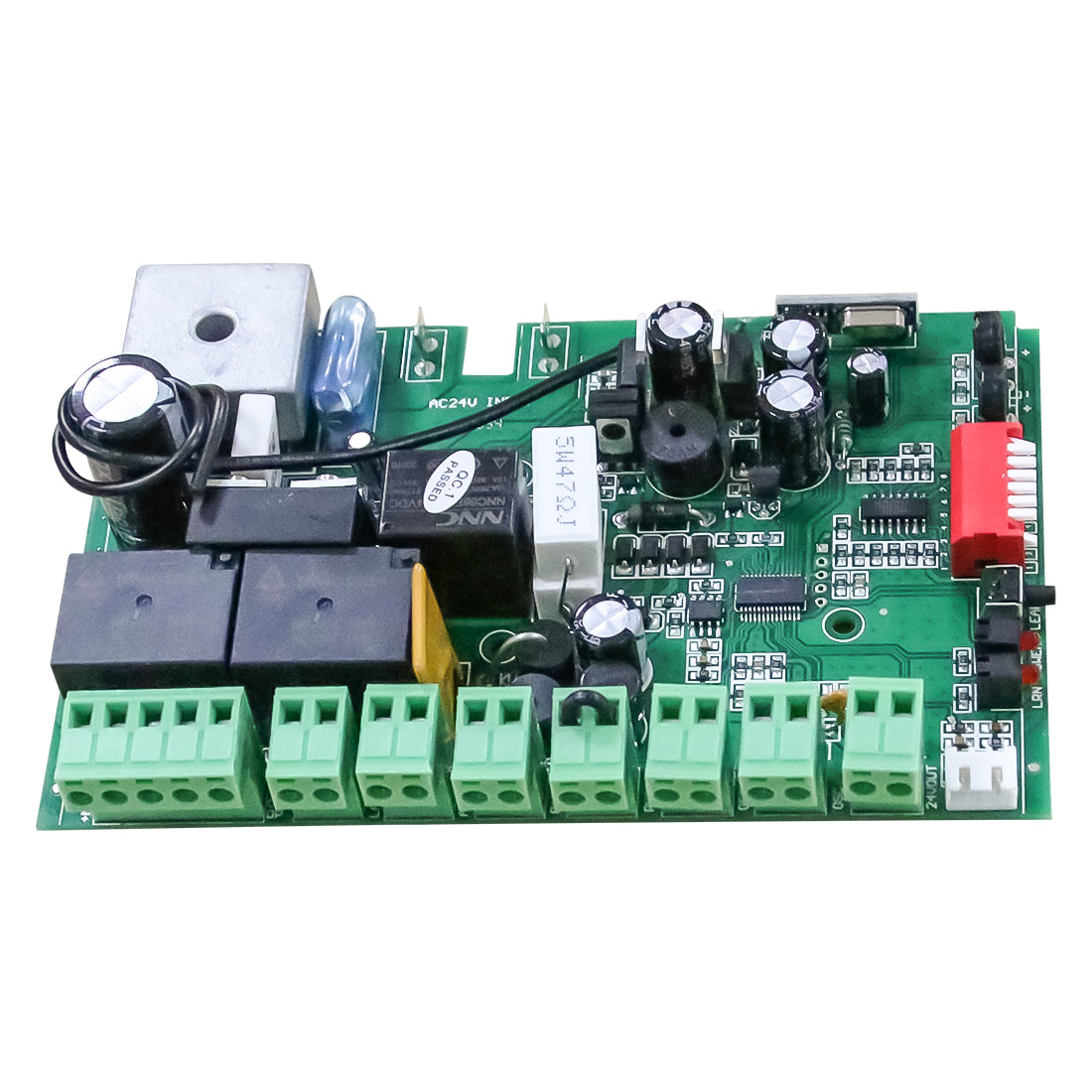

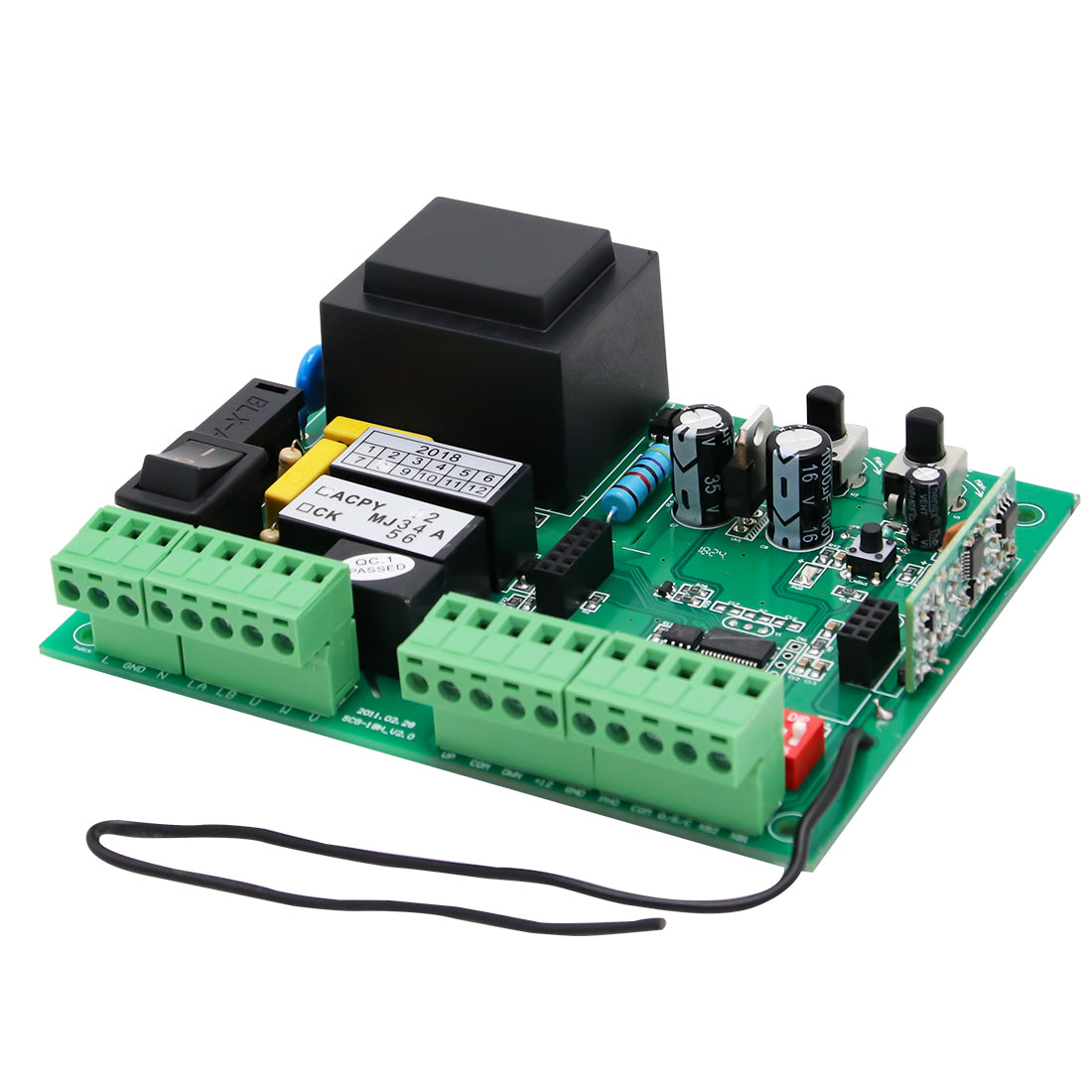

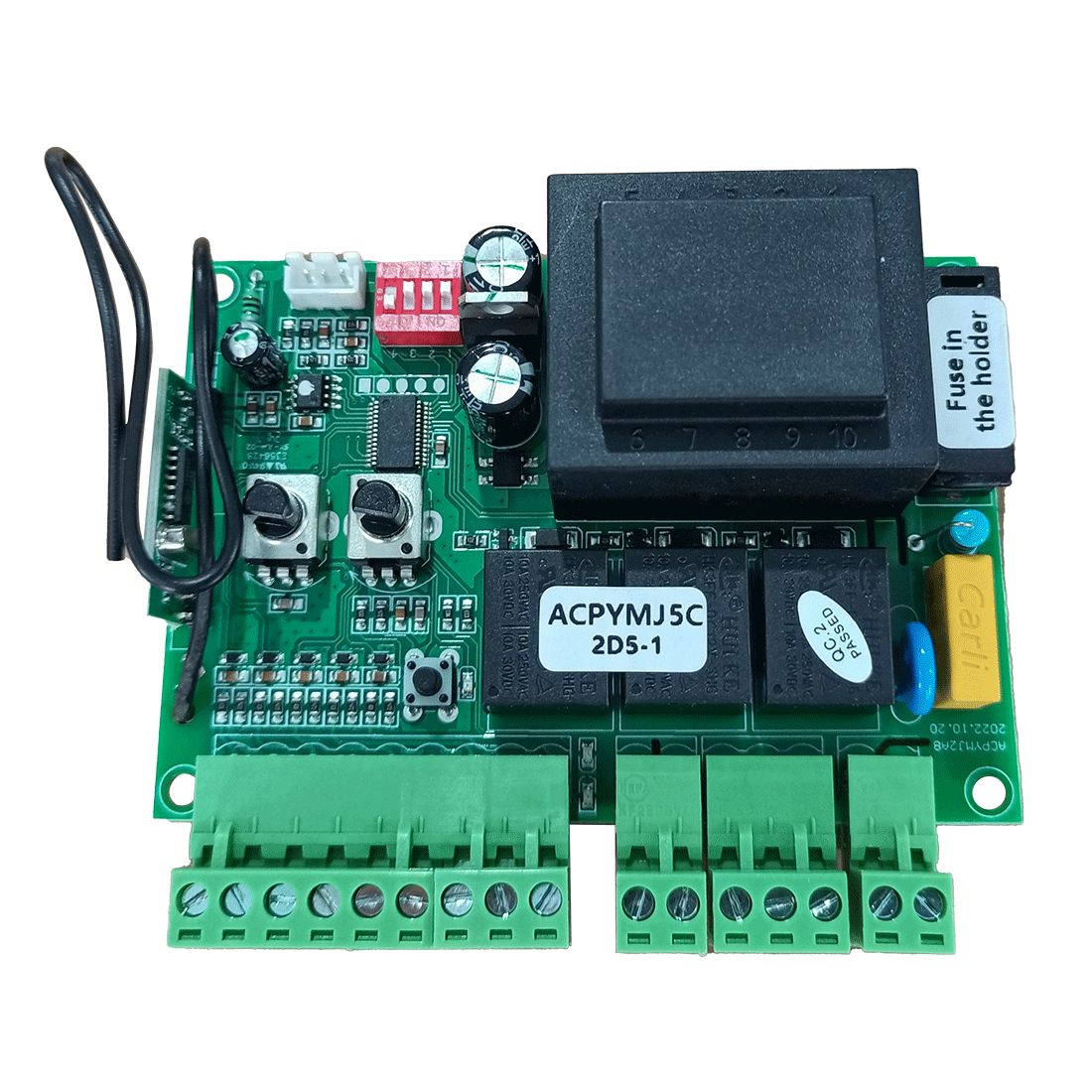

- Choose heavy-duty opener models with sufficient power, torque, and advanced safety features for windy environments.

- Install an electric gate lock to provide additional holding force, keep the gate securely closed, prevent it from being pushed open by the wind, and reduce continuous stress on the opener arms to avoid potential damage.

Usage and Maintenance Tips

- Avoid operating the gate opener during strong winds to prevent overload or damage.

- Keep the gate path clear of debris to maintain smooth and reliable operation.

- Regularly inspect gate posts, hinges, brackets, and opener arms for looseness or wear.

- In areas prone to frequent or strong winds, schedule periodic maintenance and safety checks.

- During extreme weather conditions, disconnect the power supply and manually secure the gate to prevent opener damage or safety hazards.

Wind is a major environmental factor influencing the safety, durability, and performance of swing gate openers. By selecting the right gate design, reinforcing installation components, and following proper maintenance practices, you can ensure safe, efficient, and long-lasting gate operation — even in challenging windy conditions.