Automatic swing gate openers provide convenient, remote-controlled access to your property. However, like any mechanical system, they may occasionally experience malfunctions. A common issue occurs when the motor runs but the gate opener arm fails to move—either not extending or retracting as expected.

This troubleshooting guide offers step-by-step instructions based on the arm’s current position to help diagnose and resolve the issue effectively.

1. Opener Arm Fully Extended - Motor Runs, but Arm Fails to Retract

If the arm is stuck in the fully extended position and the moving-rod does not retract:

-

Manually Reset the Arm:

Disengage the clutch and manually push the moving-rod to the middle position. Then, press the remote control to test for movement. -

Test Mechanical Engagement:

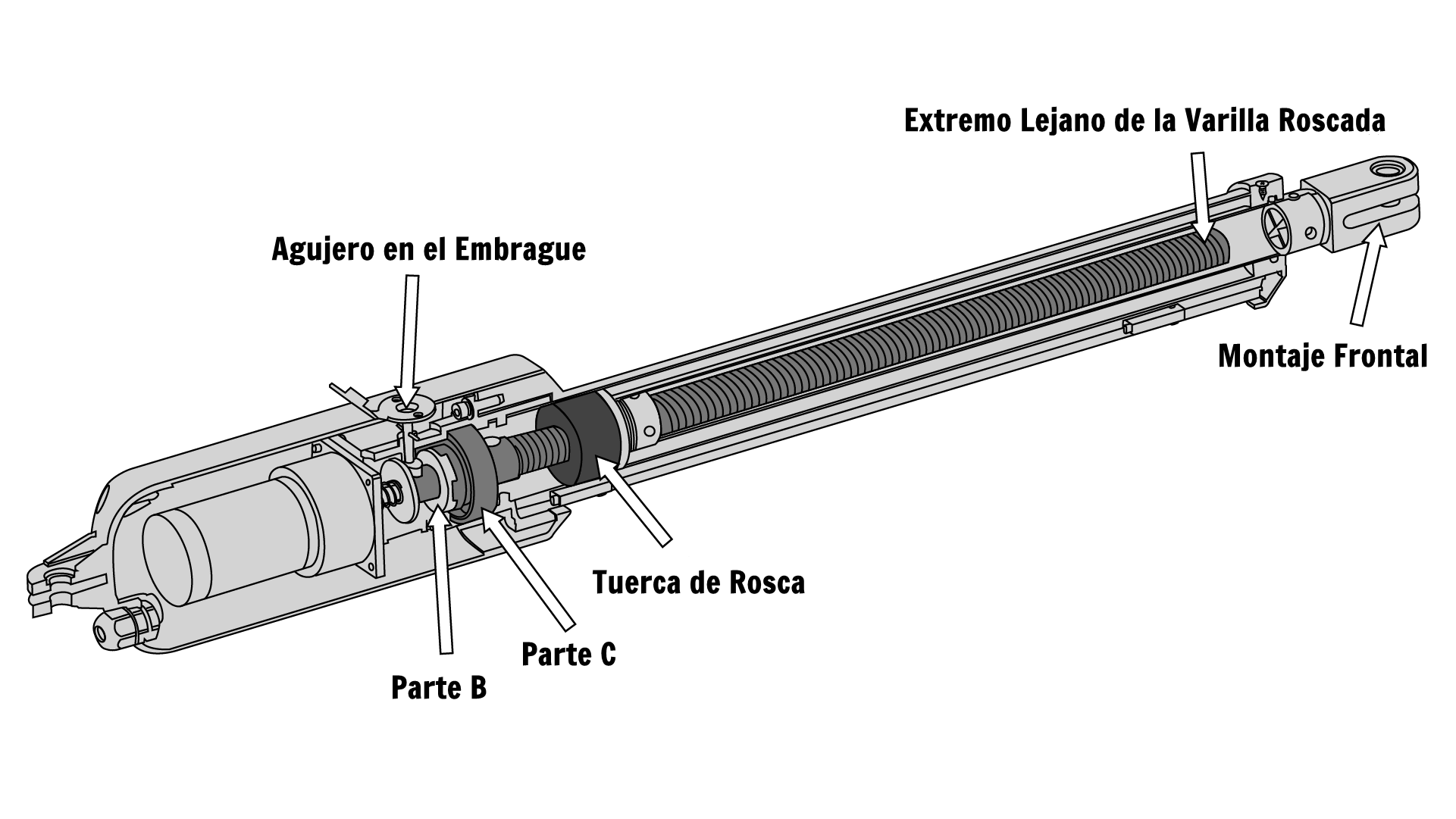

If the arm still does not move, re-engage the clutch and detach the arm from the gate. While pushing the moving-rod inward, rotate the front mount clockwise. If the arm begins to move, the screw nut may have disengaged from the screw rod at the far end. Once the arm is back in the middle position, use the remote control to test operation again.

-

Adjust the Limit Switch:

Once the arm functions properly, use a screwdriver to loosen the screw on Limit Switch B. Slide the switch slightly inward and re-tighten the screw to prevent future over-extension.

For additional guidance, refer to our article: “How to Retract the Moving-Rod When the Opener Arm Extends Too Much.”

2. Opener Arm Partially Extended or Fully Retracted - Motor Runs, but Arm Remains Stationary

If the opener arm is partially extended or fully retracted and the moving-rod does not move despite the motor activation:

-

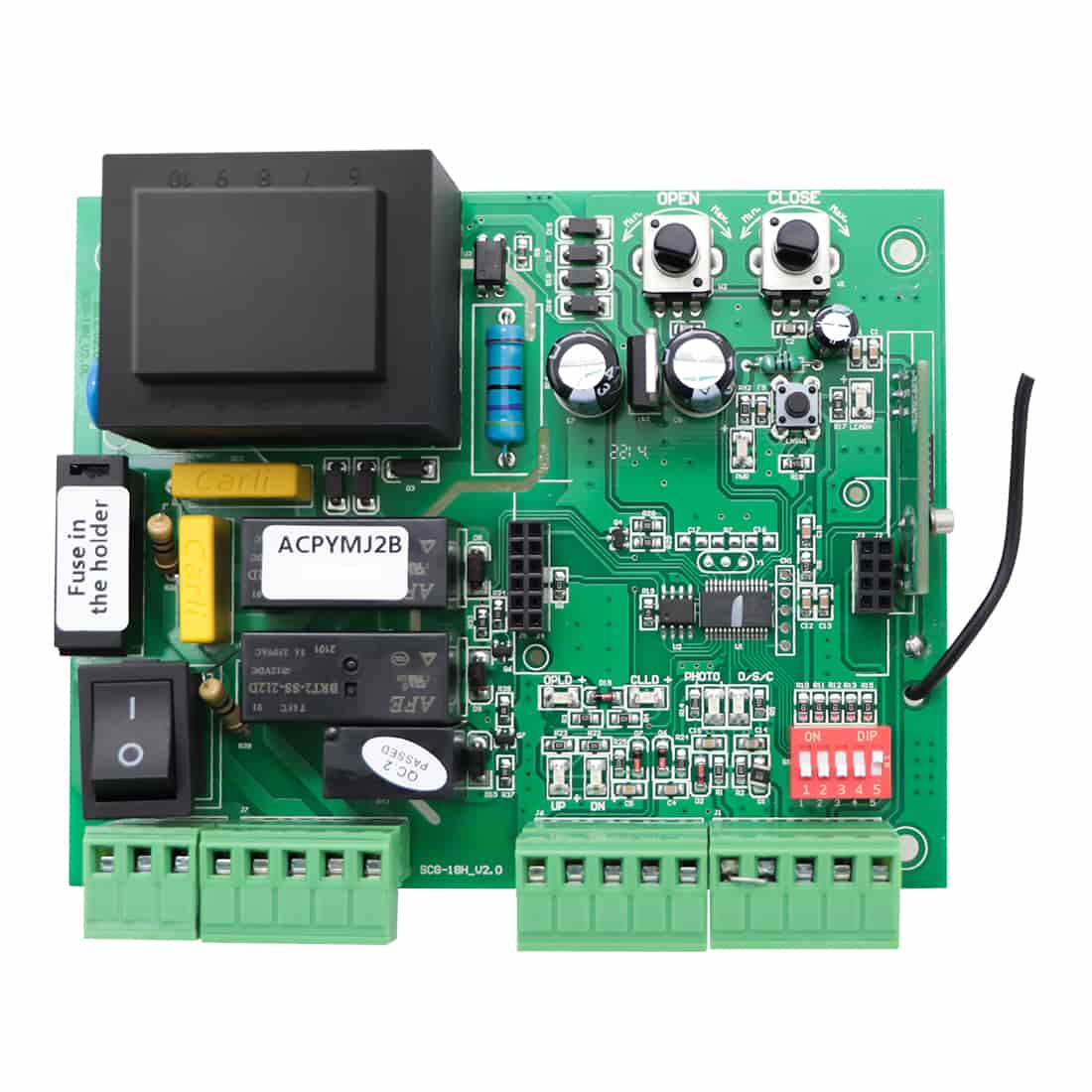

Check Clutch Engagement:

Ensure that the clutch is fully and correctly engaged. -

Inspect Clutch Functionality:

If engagement appears normal, disassemble the opener arm and check whether clutch components (Part B and Part C) are properly aligned. If not, manually rotate the front mount until proper alignment is achieved. -

Examine Mechanical Components:

Verify the connection between the screw rod and the clutch component with bearing (Part C). Also inspect the moving-rod’s screw nut for signs of damage or excessive wear. -

Assess Gearbox Integrity:

If all visible components appear intact and operational, but abnormal or excessive noise is present in the motor area, the issue may lie within the motor’s reduction gearbox. Internal gear damage or slippage can prevent the arm from moving, even if the motor is running.

By following this guide, you can determine whether the malfunction is caused by arm over-extension, clutch misalignment, mechanical disconnection, or internal gearbox failure. If the problem persists or you are unsure of the next steps, please contact our technical support team for further assistance.